Our Products

-

ALLOYS PRODUCTS

- Stainless Steels

- Duplex And Super Duplex Steel

- Nickel Alloys

- Titanium Alloys OUR PRODUCTS

- Coils

- Sheets & Plates

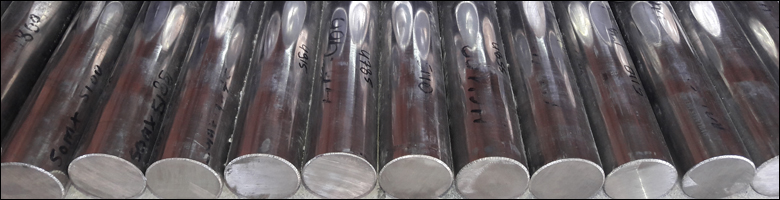

- Round Bars

- Pipes & Tubes

- Scrap

- Pure Nickel Strips & Busbars

Nickel Alloy

Nickel 200

Common Trade Names

Nickel 200

UNS#

N02200

Applications

Chemical processing and electronics, containers and piping, processing equipment, particularly to maintain product purity in handling foods, synthetic fibers and alkalies

Standards

ASTM B-162

ASME SB-162

Nickel 201

Common Trade Names

Nickel 201

UNS#

N02201

Applications

Containers and Piping

Standards

ASTM B-162

ASME SB-162

AMS 5533

Nickel Alloy 22

Common Trade Names

Hastelloy®C- 22

Inconel® 22

UNS#

N06022

Applications

Chemical processing, pollution control, flue gas desulfurization systems, sour gas services, waste incinerators, and pulp and paper processing industries.

Standards

ASTM B-575

ASME SB-575

Nickel Alloy 400

Common Trade Names

Monel® 400

UNS#

N04400

Applications

Pumps, valves, and fittings, marine engineering, chemical and hydrocarbon processing equipment, shafts,, fasteners, and heat exchangers.

Standards

ASTM B-127

ASME SB-127

AMS 4544

QQ-N-281

Nickel Alloy 600

Common Trade Names

Inconel® 600

UNS#

N06600

Applications

Furnace parts, Heat treatment fixtures, and Restaurant cooking appliances, chemical and food processing, nuclear engineering, and for sparking electrodes

Standards

STM B-168

ASME SB-168

AMS 5540

MIL-N-23228

MIL-T-23227

Nickel Alloy 601

Common Trade Names

Inconel® 601

UNS#

N06601

Applications

Heat treat baskets, Muffles, and Retorts, industrial furnaces; petrochemical and other process equipment; and gas-turbine components.

Standards

ASTM B-168

AMS 5870

Nickel Alloy 625

Common Trade Names

Inconel® 625

UNS#

N06625

Applications

Chemical processing equipment, Oil & Gas sour service flowlines, well head equipment, chemical injection lines for Oil & Gas wells, heat exchangers, aerospace and marine engineering, pollution-control equipment, and nuclear reactors.

Standards

ASTM B443

ASME SB443

AMS 5599

Nickel Alloy 718

Common Trade Names

Inconel® 718

UNS#

N07718

Applications

Aircraft ducting and engine plumbing, gas turbines, rocket motors, spacecraft, nuclear reactors, pumps, and tooling.

Standards

ASTM B-670

AMS 5596

AMS 5597

Nickel Alloy 800H

Common Trade Names

Incoloy® 800H

UNS#

N08810

Applications

Process piping, Heat treat fixtures, and Furnace parts, chemical and petrochemical processing, in power plants for super-heater and reheater tubing, in industrial furnaces, and for heat treating equipment.

Standards

ASTM B-409

ASME SB-409

AMS 5871

Nickel Alloy 825

Common Trade Names

Incoloy® 825

UNS#

N08825

Applications

Jet engine nacelles (engine pods, Jet engine parts and fasteners), chemical processing, pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production, and pickling equipment.

Standards

AMS 5525

AMS 5858

Nickel Alloy C-276, Hastelloy® C-276

Hastelloy® C-276, which is also sold as Nickel Alloy C-276, is a nickel-molybdenum-chromium wrought alloy. Hastelloy C-276 is perfect for use in situations that demand protection from aggressive corrosion and localized corrosion attack. This alloy Other important features of Nickel Alloy C-276 and Hastelloy C-276 include its resistance to oxidizers like:

● Ferric and cupric chlorides

● Organic and inorganic hot contaminated media

● Chlorine (wet chlorine gas)

● Seawater

● Acids

● Hypochlorite

● Chlorine dioxide

Nickel Alloy K-500, Monel® K-500

Special Metals popular Monel K-500 is a unique nickel-copper superalloy and offers many of the benefits of Monel 400, but with strength and hardness. These improvements are due to two main factors:

● The addition of aluminum and titanium to an already robust nickel-copper base adds strength and hardness

● Material strength and hardness is further enhanced through age hardening

Though used for a wide variety of applications, Monel alloy K-500 is specifically popular in a number of fields including:

● Chemical Industry (valves and pumps)

● Paper Production (doctor blades and scrapers)

● Oil and Gas (pump shafts, drill collars and instruments, impellers, and valves)

● Electronic components and sensors

Nickel Alloy X-750, Inconel® X-750

Inconel® X-750, also known as Nickel Alloy X-750, is popular and cost-effective precipitation-hardenable nickel-chromium alloy. Inconel X-750s wide spread use is due to its numerous benefits which include:

● High strength at temperatures to 1500°F (816°C) after suitable heat treatment

● Creep-rupture strength at high temperatures to about 700oC (1290oF)

● High tensile and creep-rupture properties

● Resistance to a wide variety of industrial corrosives under both oxidizing and reducing conditions

● Excellent workability including machinability and welding

● Resistance to chloride ion stress-corrosion cracking

● Precipitation hardenable